Designing a tile adhesive formulation that meets C2 requirements can be challenging. This is because the product must pass all tensile adhesion strength tests:

-

Initial tensile adhesion

-

After water immersion

-

After heat ageing

-

After freeze-thaw cycles

-

Open time

Many believe that the key to achieving C2 performance lies in increasing the dosage of redispersible polymer powder (RDP). While this might help in some cases, simply adding more RDP often fails to solve the problem and instead leads to higher production costs. In fact, too much RDP—especially VAE-based—can negatively affect the tensile adhesion strength after water immersion, as the polymer tends to soften after prolonged water exposure.

Others try to compensate by increasing the cement content to enhance strength. However, this approach also has drawbacks: it shortens the open time and increases material costs.

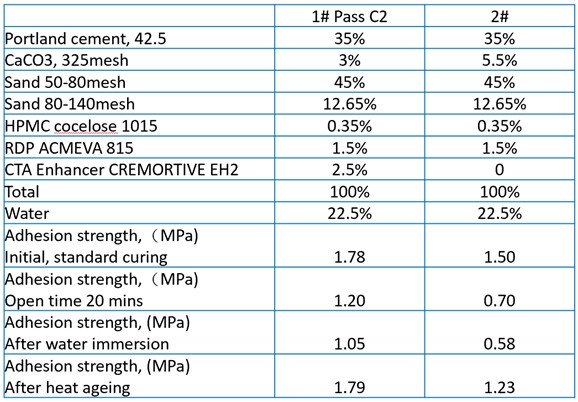

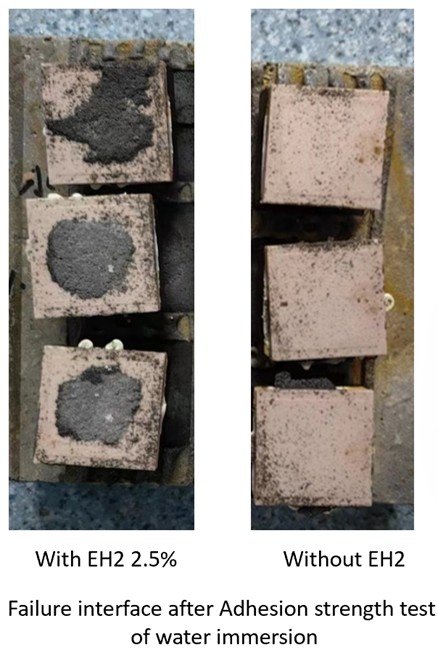

To address this challenge, I recommend using a tile adhesive enhancer called EH 2 in your C2 formulation.

The table below shows test formulations and results. As you can see, Formulation #1, which contains only 1.5% RDP and 2.5% EH 2, successfully meets C2 performance standards. Moreover, the unit cost of EH 2 is lower than that of conventional RDP, making it a more cost-effective solution.

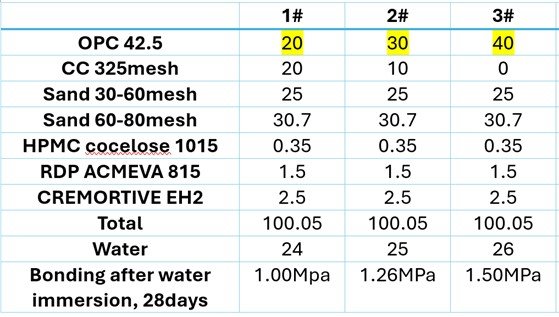

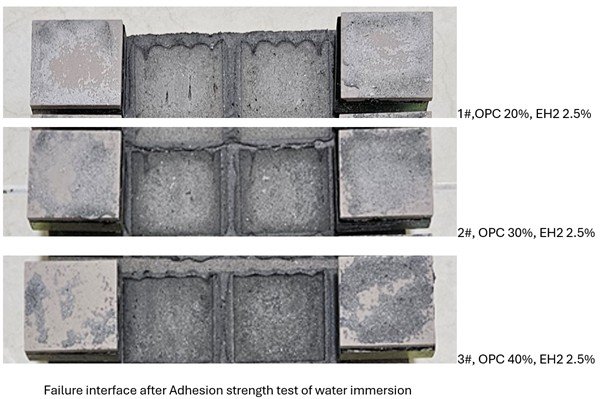

In another test, EH 2 demonstrated its ability to reduce the cement content in the formulation—using only 20% of the typical cement dosage in total formulation—while still passing the tensile adhesion strength after water immersion. This makes tile adhesive with EH 2 especially suitable for use in regions with long rainy seasons.